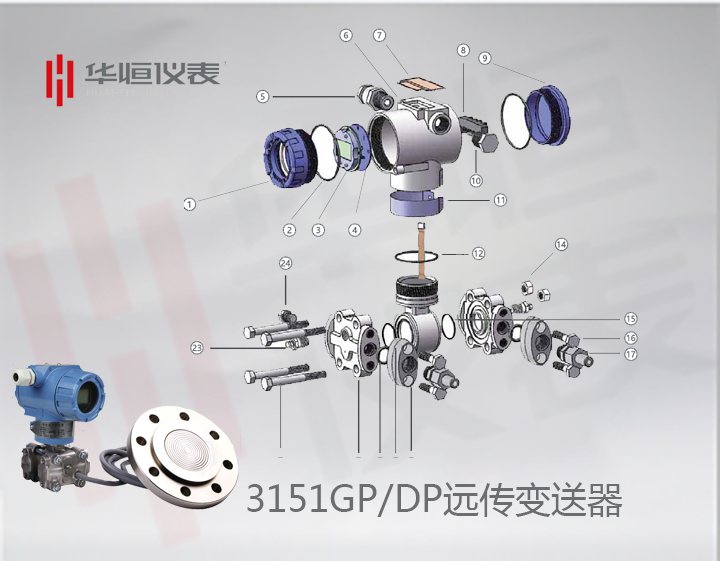

3151智能型液位变送器直装型结构都有什么?

压力变送器是一种将压力转换成气动信号或电动信号进行控制和远传的设备。 它能将测压元件传感器感受到的气体、液体等物理压力参数转变成标准的电信号(如4~20mADC等),以供给指示报警仪、记录仪、调节器等二次仪表进行测量、指示和过程调节。用于各种工业自控环境,涉及水利水电、铁路交通、智能建筑、生产自控、航空航天、军工、石化、油井、电力、船舶、机床、管道等众多行业。

Pressure transmitter is a kind of equipment that converts pressure into pneumatic signal or electric signal for control and remote transmission. It can transform the physical pressure parameters such as gas and liquid sensed by the pressure sensor into standard electrical signals (such as 4 ~ 20mADC, etc.), and supply the secondary instruments such as indicator alarm, recorder and regulator for measurement, indication and process adjustment. It is used in various industrial automatic control environments, including water conservancy and hydropower, railway transportation, intelligent building, production automatic control, aerospace, military industry, petrochemical, oil well, power, ship, machine tool, pipeline and many other industries.

压力变送器有电动式和气动式两大类。电动式的统一输出信号为0~10mA、4~20mA或1~5V等直流电信号。气动式的统一输出信号为20~100Pa的气体压力。

There are two types of pressure transmitter: electric type and pneumatic type. The unified electric output signal is 0-10mA, 4-20mA or 1-5V DC electrical signal. The unified output signal of pneumatic type is the gas pressure of 20-100pa.

3151智能型液位变送器直装型结构都有什么?/主要性能

What is the direct mount structure of 3151 intelligent liquid level transmitter? / main performance

1、使用被测介质广泛,可测油、水及与316不锈钢和304不锈钢兼容的糊状物,具有一定的防腐能力;

1. It can measure oil, water and paste compatible with 316 stainless steel and 304 stainless steel. It has a certain anti-corrosion ability;

2、高准确度、高稳定性、选用进口原装传感器,线性好,温度稳定性高;

2. High accuracy, high stability, imported original sensor, good linearity, high temperature stability;

3、体积小、重量轻、安装、调试、使用方便;

3. Small size, light weight, easy to install, debug and use;

4、不锈钢全封闭外壳,防水好;

4. Stainless steel fully enclosed shell, waterproof;

5、压力传感器直接感测被测液位压力,不受介质起泡、沉积的影响。

5. The pressure sensor directly senses the measured liquid level pressure, which is not affected by medium foaming and deposition.

3151智能型液位变送器直装型结构都有什么?/压力传感器使用过程应注意考虑下列情况:

What is the direct mount structure of 3151 intelligent liquid level transmitter? / pay attention to the following situations during the use of pressure sensor:

1、防止变送器与腐蚀性或过热的介质接触;

1. Prevent the transmitter from contacting with corrosive or overheated media;

2、防止渣滓在导管内沉积;

2. Prevent dross from depositing in the conduit;

3、测量液体压力时,取压口应开在流程管道侧面,以避免沉淀积渣;

3. When measuring the liquid pressure, the pressure tap shall be opened at the side of the process pipe to avoid the deposition of slag;

4、测量气体压力时,取压口应开在流程管道顶端,并且变送器也应安装在流程管道上部,以便积累的液体容易注入流程管道中;

4. When measuring the gas pressure, the pressure tap shall be opened at the top of the process pipe, and the transmitter shall also be installed at the top of the process pipe, so that the accumulated liquid can be easily injected into the process pipe;

5、导压管应安装在温度波动小的地方;

5. The pressure pipe shall be installed in the place with small temperature fluctuation;

6、测量蒸汽或其它高温介质时,需接加缓冲管(盘管)等冷凝器,不应使变送器的工作温度超过极限;

6. When measuring steam or other high-temperature medium, it is necessary to connect a condenser such as a buffer pipe (coil) to prevent the working temperature of the transmitter from exceeding the limit;

7、冬季发生冰冻时,安装在室外的变送器必需采取防冻措施,避免引压口内的液体因结冰体积膨胀,导至传感器损坏;

7. When freezing occurs in winter, the transmitter installed outdoors must take anti freezing measures to prevent the liquid in the pressure tap from expanding due to the frozen volume, leading to the sensor damage;

8、测量液体压力时,变送器的安装位置应避免液体的冲击(水锤现象),以免传感器过压损坏;

8. When measuring the liquid pressure, the installation position of the transmitter should avoid the impact of liquid (water hammer phenomenon), so as to avoid the sensor overpressure damage;

9、接线时,将电缆穿过防水接头(附件)或绕性管并拧紧密封螺帽,以防雨水等通过电缆渗漏进变送器壳体内。

9. When wiring, put the cable through the waterproof connector (accessory) or winding pipe and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

在华恒仪表制造厂家看来,具有比较高稳定性是作为3151系列仪表制造中很重要的生产基础,立足于西安华恒仪表生产厂家的华恒仪表,以核心的电路板生产制造和金属电容/扩散硅传感器完全自主的能力,为广大厂商提供特殊订制,复杂工况专业设计,大宗客户贴牌生产等一线式服务.